How does an Automated Optical Inspection Machine work?

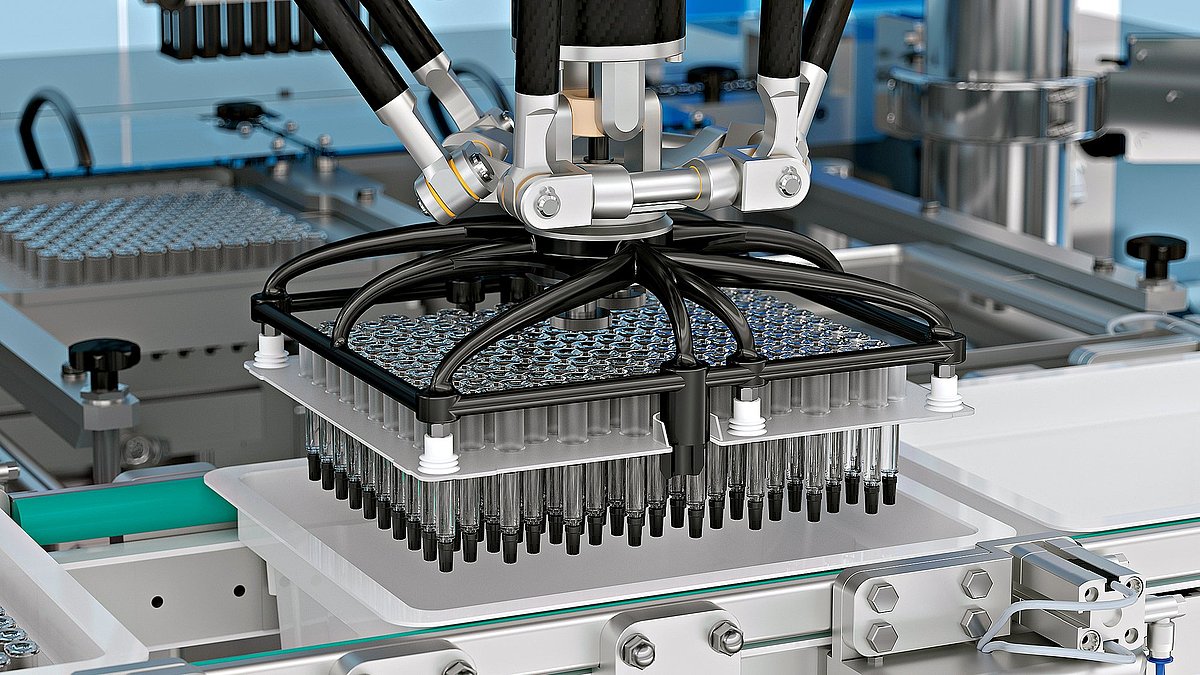

Automatic optical inspection machines (AOI machines) are used to perform vision inspections automatically. This type of machine is capable of examining practically any object that requires a precise visual inspection.

Oftentimes, this method is used to ensure that the quality of products leaving a production line is of the highest standard – without any manufacturing or assembly defects occurring during production.

Automatic Optical Inspection (AOI): The Need

Although technology has made significant advancements, circuit boards are undoubtedly more complex than they were a few years ago. Therefore, AOI solutions are required.

Surface mount technology and the consequent ensuing decrease in board size have led to boards being remarkably compact. Most issues occur at the soldered joints, where even moderate boards have a substantial number of them.

Due to the increase in complexity of boards, manual inspection is not an option anymore. While manual inspection is acceptable, it has limited effectiveness.

This is because inspectors tend to get tired easily, and incorrect construction may thus go unnoticed. A computerized inspection is therefore necessary to speed up and increase the efficiency of the inspection – without the operator having to put in so much effort.

As a cost-effective strategy of integrated electronics testing, the AOI inspection machine is also used as an integrated optical inspection machine. The system helps in detecting faults early in the production line since the marketplace demands a high volume of high-quality products to be sold very reliably and quickly.

For checking and ensuring that the quality of the products is 100%, a fast and reliable method is necessary. An automatic optical inspection machine is the perfect solution. In addition to being able to be used immediately after soldering, the AOI machine also has other advantages.

In this way, problems can be spotted earlier in the production process, which is beneficial. There are many advantages to the automatic optical inspection machine, such as the fact that it allows early detection of process problems in the soldering and assembly areas.

The Automatic Programming of Optical Inspection Machines

To test a PCB assembly, the AOI machine must be programmed with the details of an acceptable board. The automated optical inspection machine must also be programmed correctly for any faults to be detected.

Here are two methods for programming an AOI machine:

- The Golden Board: When using this method, a known good board is used as the target for an AOI machine. During the process, this board is inspected for the crucial attributes. The machine looks at the components and evaluates the solder profiles of the joints and many other factors.

- Method of algorithm-based programming: This method requires real boards, but fewer than the golden board method. The PCB data is provided to the AOI machine in order to generate a profile.

Briefly

During production, it is very important to inspect the boards at the end of the line. It allows the quality of the boards to be monitored, and any problems detected and corrected early on are prevented from occurring again.